Piezo Element

Piezo Sound Component

Piezo Buzzer

Passive Piezo Buzzer

Active Piezo Buzzer

Self Drive Piezo Buzzer

Piezo Buzzer Pinout

Piezo Buzzer Leadwire

Piezo Ultrasonic Transducer

What Is Piezo Buzzer?

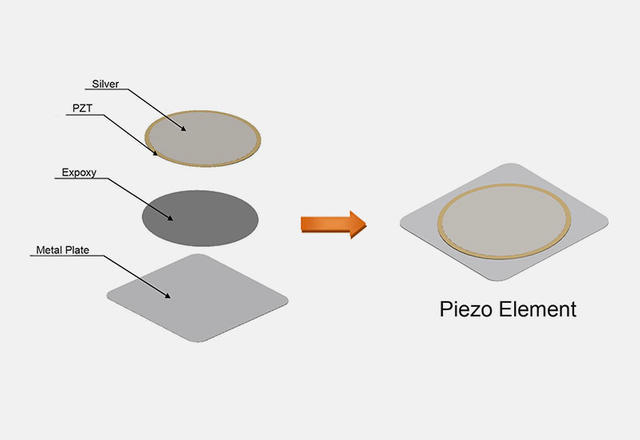

A buzzer is an audio signalling device, among which magnetic and piezo are the two most common catagories. A buzzer is also known as a sounder, audio alarm or audio indicator. A piezo buzzer contains a piezo element, which is a thin disk of piezo ceramic gluing to a metal plate (brass or stainless steel, etc. ). Both sides of the piezo ceramic disk have a silver electrode printed to allow for electrical contact. Piezo element is the main souce for the sound of a piezo buzzer.

Kailitech piezo ceramic products include piezo elements, piezo buzzers, piezo ultrasonic transducers and piezo speakers, hereby below we mainly introduce Kailitech piezo elements, and the 3 types of piezo buzzers: passive piezo buzzer, active piezo buzzer and self drive piezo buzzer.

Kailitech Piezo Elements

The piezo element is the heart of a piezo buzzer, which is also known as piezoelectric diaphragm or piezo benders. Kailitech manufactures full kinds of piezo elements including: 1, external drive piezo element 2, external drive piezo element with leads 3, self-oscillating piezo element 4, self-oscillating piezo elelment with leads.

Working Principle of Piezo Buzzers

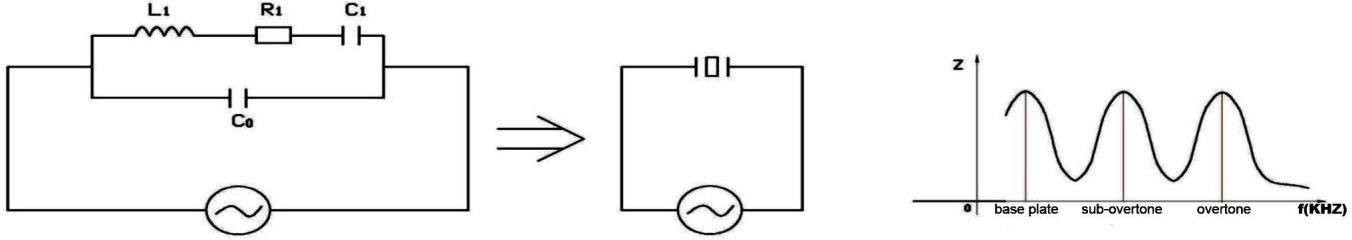

A piezo buzzer is composed of piezo element, casing, terminal and with/without circuit board. The piezo element is the heart of the piezo buzzer. Here is the electrical equivalent circuit of a piezo element:

*L1, R1, C1, are respectively the inductance, resistance and capacitance at resonance, and C0 is the static capacitance.

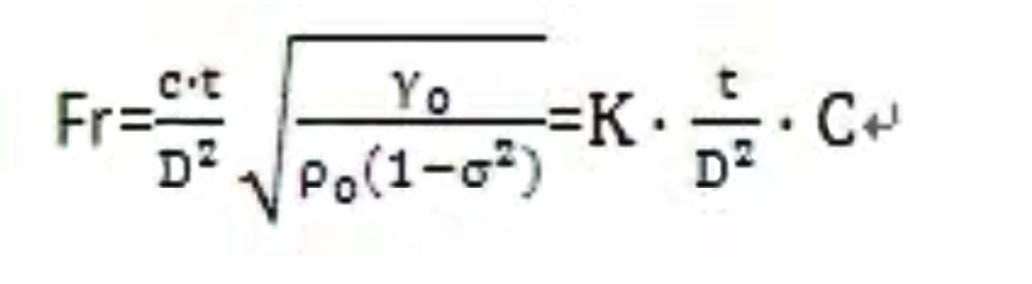

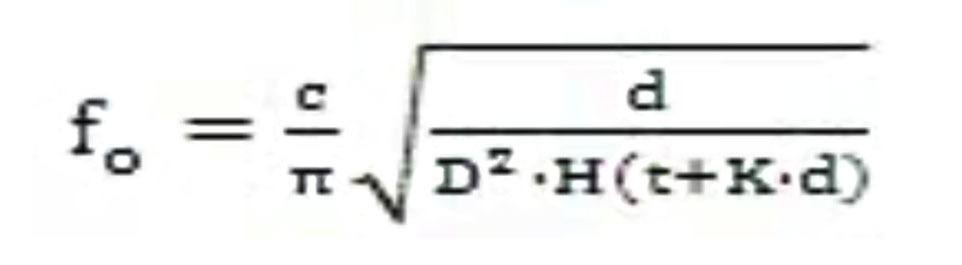

Therefore, the piezo element is actually a LC oscillator circuit. When an alternating signal is input, it will oscillate and deform to make a sound. When the input frequency reaches the same phase as the signal voltage and current, it will resonate. This frequency is called the resonant frequency ( Fr).

*K: constant figure

*t: total thickness of piezo element

*D: diameter of piezo element

*C: supporting mode coefficient, as below:

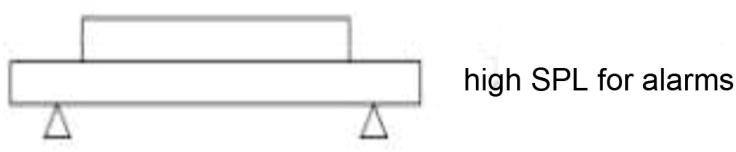

﹡C= 0.412 for

Node Supporting Mode:

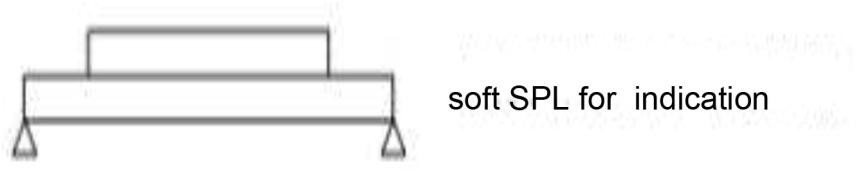

﹡C= 0.233 for

Edge Supporting Mode:

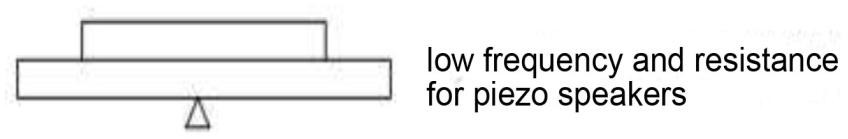

﹡C= 0.172 for

Centre Supporting Mode:

To achieve higher sound pressure and sensitivity, piezoelectric materials must be of good performance. When applying constant voltage( V), the micro-displacement (deformation) of the piezo element is:

*Kp: The flat electromechanical coupling coefficient of Piezoelectric material

*E33T:Dielectric constant

*D31: Piezoelectric constant

Only materials with higher D31, Kp, and E33T can produce large micro- displacement and generate high sound pressure. Therefore, good quality piezoelectric material is the key to the performance of the piezo element.

Yet, the piezo element alone is difficult to match the acoustic impedance of the air and to get high sound pressure level. It must be combined with an acoustic resonator to amplify the sound, increase the sound pressure output, and improve the frequency characteristics.

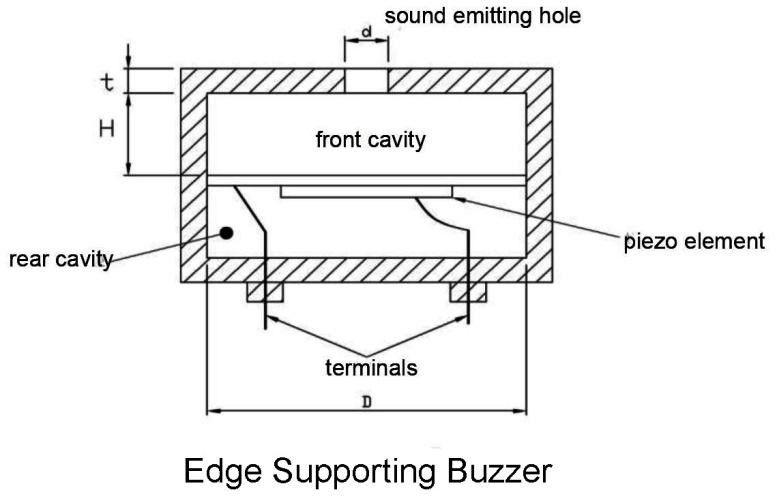

The acoustic resonator is composed of case (resonance cavity), sound cavity (divided into front cavity and rear cavity), sound emitting hole and with or without circuit board.

The resonance frequency of the acoustic resonator is also called the inherent frequency ( fo) of the acoustic resonator:

﹡C:Sound Speed

﹡∏:constant 3.14

﹡K:constant ≈1.3

﹡d:diameter of the sound emitting hole

﹡t :the thickness of the sound emitting hole

﹡D:edge support diameter ≈ piezo element diameter

﹡H:depth of front acoustic cavity

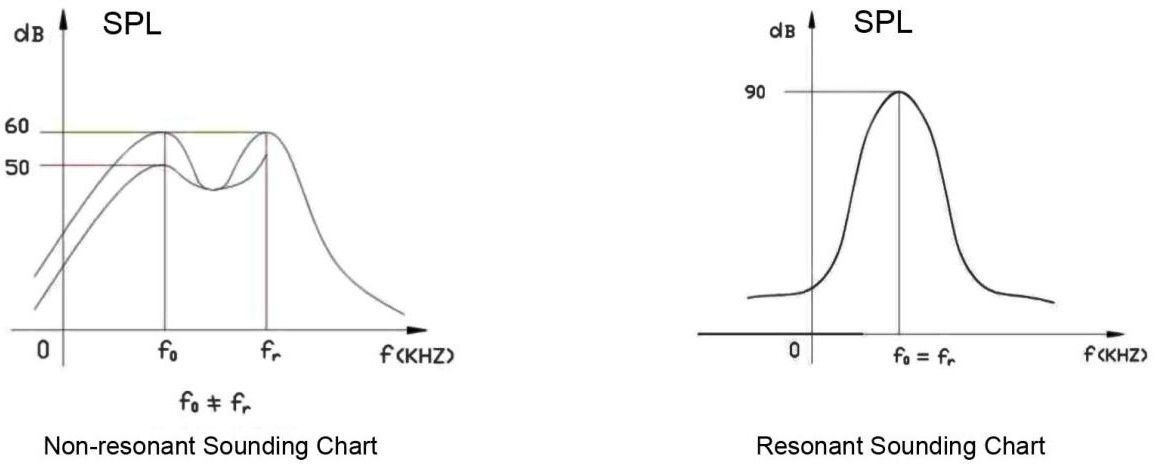

It is assumed that the highest and most stable SPL is emitted at resonance frequency. Only when the fo of the acoustic resonator is consistent with the fr of the edge supporting buzzer, the two will resonate, the sound is superimposed, and the sound pressure reaches the highest, with the least input power, as shown in the following figure:

Therefore, when designing buzzer, how to perfectly match the acoustic resonator and piezo element becomes the key to the development of high-quality buzzers, which involves comprehensive applications in many fields such as chemistry, electronics, structure, and acoustics.

Kailitech has established an independent R & D centre, integrating production, education and research. Kailitech lab has full range of R&D equipments, such as wide-width sweep frequency tester, material granularity analyzer, d33 tester, spectrum analyzer, metallographic microscope, etc., as well as reliability verification test equipments which guarantees reliabilities for the new products testing, with great advantages to design and manufacture customerized models.

Types of Piezo Buzzer

Kailitech piezo buzzers can be assoted into three types: passive piezo buzzer, active piezo buzzer and self drive piezo buzzer.

Passive piezo buzzer

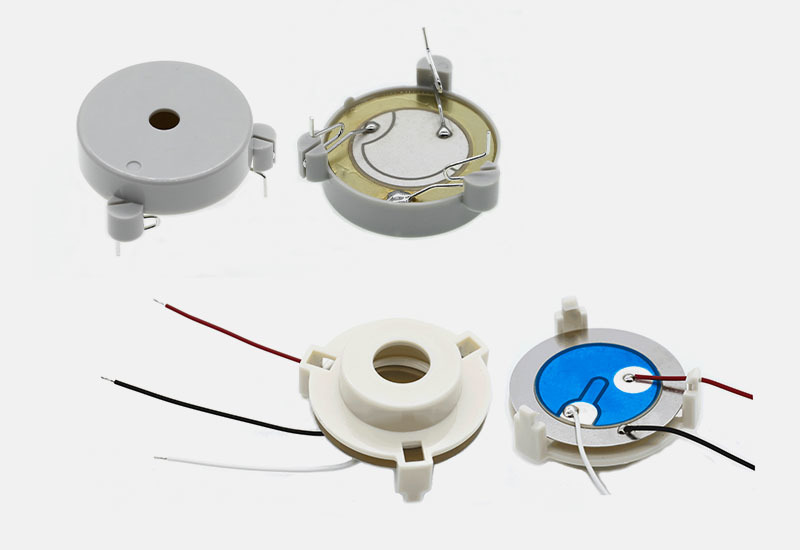

Passive piezo buzzer, which is known as piezo transducer as well, consist of a casing, a piezo element and a terminal. The passive piezo buzzer requires a signal source which will set the sound signal parameters.

Active piezo buzzer

Active piezo buzzer, which is known as piezo indicator as well, consist at least of a casing, a piezo element, a circuit board and a terminal, and can generate sound by applying a DC voltage.

Piezo Buzzer's Wide Application

Home Appliances

Piezo buzzers are suitable for all kinds of home appliances where a prompt tone for settings or the indication tone for completion is required, such as air conditioners, refrigerators, washing machines, micro ovens, rice cookers, Induction cookers and high speed blenders…..

Why Choose Our Piezo Buzzer

Piezo buzzers has been more and more popularily used as there is no magnetic field and no coil inside. Typically, piezo buzzers consume less current (less than 30mA), have a broader frequency range (2-6kHz) and wider operating voltage (3- 250V), and generate a higher SPL.

Kailitech piezo buzzers include types of taping, SMD, ultra-low frequency, high SPL, waterproof, high temperature and pressure resistant, with diameter or length and width fm 9.0mm to 100mm, height fm 1.8mm to 65mm, with resonant frequency range fm 200Hz to 15kHz and SPL range fm 65dB to 120dB. Housing material can be ABS, pbt, ppo, LCT, etc.

The main characteristics of Piezo Buzzers are >>

Smaller size, lighter weight, suitable for installation on various circuit boards.

High electric – acoustic power conversion efficiency (above 75%) .

Low power consumption, P≤3V*10mA=0.03W.

High reliability, long durability. The performance and degradation is the log relationship, and the degradation of performance is less than about 5% in 30 years.

No magnetic field, no coil, no electromagnetic interference.

Recommend Products