3.2khz Acoustic Transducer External Drive Piezo Element

Model:KD-34.5S-32E Dimension:34.55mm*0.55mm Resonant Frequency:3.2±0.5 kHz

Service Hotline

Keywords:

Passive Piezo Buzzer、Active Piezo Buzzer、Piezo Element、Piezo Ultrasonic Component、Piezo Speaker

Category:

■ Data Sheet

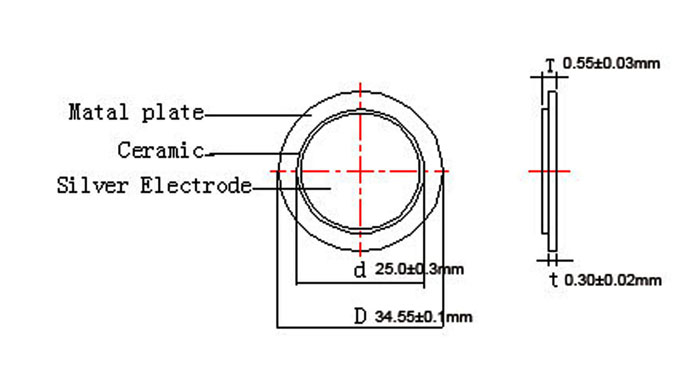

| No. | Part Number | KD-34.5S-32E |

| 1 | Resonant Frequency | 3.2±0.5 kHz |

| 2 | Resonant Impedance | 250Ω Max. |

| 3 | Static Capacitance | 40.0nF±30% at 100Hz |

| 4 | Allowable input Voltage | 30Vp-p max. |

| 5 | Operating Temperature Range | -20~+70 ℃ |

| 6 | Storage Temperature Range | -30~+80 ℃ |

| 7 | Plate Diameter | D=34.55±0.1mm |

| 8 | Ceramic Disc Diameter | d=25.0±0.3mm |

| 9 | Plate Thickness | t=0.30±0.02mm |

| 10 | Total Thickness | T=0.55±0.03mm |

| 11 | Plate Material | SUS 304 |

■ Dimension Drawings

Introducing our cutting-edge 3.2kHz Acoustic Transducer with External Drive Piezo Element, a revolutionary product designed to meet the diverse needs of modern acoustic applications. This transducer combines the precision of a 3.2kHz frequency with the efficiency of an external drive piezo element, offering unparalleled performance and reliability.

At the heart of our 3.2kHz Acoustic Transducer is the External Drive Piezo Element, which plays a crucial role in converting electrical energy into acoustic energy and vice versa. Piezoelectric materials possess the unique property of deforming when an electric field is applied and generating an electric charge when mechanically stressed. Our carefully selected piezo element, with its optimized design for external drive, ensures high - sensitivity and efficient energy conversion, enabling the transducer to produce clear and powerful acoustic signals at the precise 3.2kHz frequency.

This 3.2kHz Acoustic Transducer with External Drive Piezo Element has a wide range of applications. In the field of non - destructive testing, it can be used to detect flaws and defects in materials. The 3.2kHz frequency allows for effective penetration and reflection of acoustic waves, providing accurate information about the internal structure of the tested object. In underwater communication and sonar systems, the transducer's consistent 3.2kHz output helps in sending and receiving signals over long distances with minimal distortion. Additionally, it is suitable for use in medical imaging, where its high - frequency acoustic waves assist in creating detailed images of internal organs.

One of the key advantages of our product is its high - quality construction. The External Drive Piezo Element is made from top - grade materials that are resistant to wear, temperature changes, and environmental factors. This ensures the transducer's long - term stability and durability, reducing the need for frequent replacements. The 3.2kHz Acoustic Transducer is also engineered with precision, guaranteeing consistent performance across different operating conditions.

Furthermore, our 3.2kHz Acoustic Transducer with External Drive Piezo Element is designed for easy integration. Its compact size and standard interface make it convenient to incorporate into various systems, whether it's a complex industrial setup or a small - scale research project. We also provide comprehensive technical support to assist our customers in optimizing the performance of the transducer in their specific applications.

In the manufacturing process, strict quality control measures are implemented. Each 3.2kHz Acoustic Transducer with External Drive Piezo Element undergoes a series of rigorous tests, including frequency response testing, power handling testing, and environmental stress testing. These tests ensure that the product meets the highest industry standards and can perform reliably in real - world scenarios.

Why Choose Our Piezo Buzzer

Piezo buzzers has been more and more popularily used as there is no magnetic field and no coil inside. Typically, piezo buzzers consume less current (less than 30mA), have a broader frequency range (2-6kHz) and wider operating voltage (3- 250V), and generate a higher SPL.

Kailitech piezo buzzers include types of taping, SMD, ultra-low frequency, high SPL, waterproof, high temperature and pressure resistant, with diameter or length and width fm 9.0mm to 100mm, height fm 1.8mm to 65mm, with resonant frequency range fm 200Hz to 15kHz and SPL range fm 65dB to 120dB. Housing material can be ABS, PBT, PPO, LCP, etc.

The main characteristics of Piezo Buzzers are >>

Smaller size, lighter weight, suitable for installation on various circuit boards.

High electric – acoustic power conversion efficiency (above 75%) .

Low power consumption, P≤3V*10mA=0.03W.

High reliability, long durability. The performance and degradation is the log relationship, and the degradation of performance is less than about 5% in 30 years.

No magnetic field, no coil, no electromagnetic interference.

Peizo Buzzers' Markets

Home Appliances

Medical Devices

Safety & Security

Transportation Equipment

Consumer Electronics

IOT

They all chose us

With 30 years of research and development experience, Kailitech is professional in design and develop piezoelectric components according to customer applications. "Customer-oriented, honest and trustworthy, innovative and continuously upgrading" is our aim. Kailitech will consistently provide customers with product value and technical services with rich industry experience and professional knowledge.

FAQ

What are the piezo sound component called?

Piezo Elements, Sounders, Transducers, buzzers, Audio alarms and indicators, and various combinations of these terms.

How does Kailitech sound component part number system works?

Kailitech part number system.

Please give me diagrams of the Feedback Electrode Shape and Recomend Driving Circut of your self drive type piezo transducers.

Recomend Driving Circut for seld drive piezo transducers.

Feedback electrode shape.

What are the mounting options?

Pin-type, Pin-type taping, SMD, Flange Mount & Terminal type.

What tones are available?

Continuous, Fast Pulse, Ultra Loud Siren, Ultra Loud Warble Series, and Continuous/Pulse Dual Tone.

How are they constructed?

Exploded piezo buzzer Diagram.

What are the mounting options?。

Pin-type, SMD, Flange Mount, Terminal type and Panel Screw Terminals.

Product Consultation

*Note: Please fill in the information accurately for smooth communication, and we will contact you as soon as possible

Recommend Products